Zoe Askew

The Maryvale Energy from Waste (EfW) project, led by consortium partners Opal, Veolia, and Masdar Tribe Australia, recently signed a grant agreement for $48.2 million under the Manufacturing Collaboration Stream of the Modern Manufacturing Initiative (MMI) after receiving grant funding from the Australian Government as part of the Modern Manufacturing Strategy.

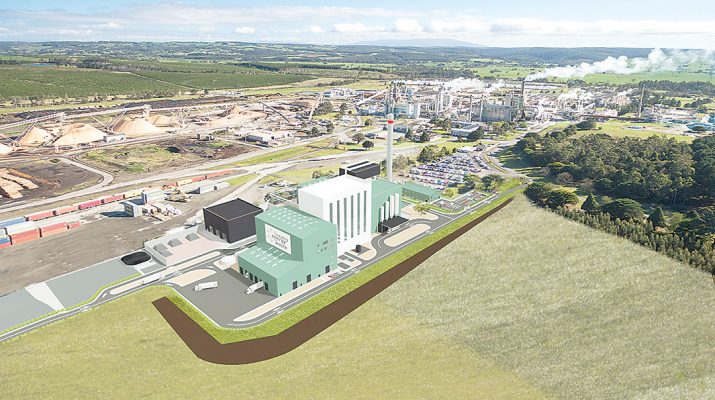

The Maryvale EfW facility, to be constructed at the Opal Australian Paper’s Maryvale Mill in the Latrobe Valley, will be the first of its kind in Australia to recover heat and power from residual non-recyclable municipal and commercial waste to provide partly renewable power for large-scale manufacturing.

Veolia, a company that designs and deploys water, waste and energy management solutions that contribute to the sustainable development of cities and industries, already operates 65 state-of-the-art EfW facilities worldwide, and will operate and maintain the Maryvale EfW facility.

Speaking on behalf of the consortium, Edward Nicholas, General Manager of Masdar Tribe Australia, said that the grant demonstrates the Australian Government’s commitment to supporting innovative, alternative energy sources for manufacturing.

“The funding support from the Commonwealth not only demonstrates the importance of this technology in providing a waste management solution to a whole-of-community problem, but it also accelerates our project towards completing the development phase and commencing construction,” Mr Nicholas said.

The Maryvale EfW facility will provide councils and businesses with a competitive waste management solution to divert residual waste from landfills and reduce greenhouse gas emissions. Contracts will be offered on a waste arising basis, enabling councils to have the freedom to pursue future waste reduction initiatives without penalty.

“The social, environmental and economic case to send non-recyclable waste to the Maryvale EfW facility is compelling,” Mr Nicholas said.

“With finite capacity and heightened interest, forward-thinking Councils are moving quickly to secure this opportunity while it’s still available.”

The Maryvale EfW project will attract investment capital of over $600 million to the Latrobe Valley, and the state-of-the-art infrastructure supports the sustainable growth of an innovative energy industry in the Gippsland region.

It will create more than 500 jobs in Victoria and Gippsland during the construction phase, and support an estimated 450 Victorian jobs once operational, including direct and flow-on.

Maryvale EfW facility will feature world-class leading technology that provides superior reliability, compliance to stringent emissions standards, superior energy efficiency and more than 99 per cent diversion of waste away from landfill consistent with circular economy principles.

The state government welcomed advancements to the Maryvale EfW project, simultaneously implementing a cap on the amount of waste that can be heated treated to make energy.

“We welcome the investment and job creation this project brings to the region,” a state government spokesperson said.

“As Victoria shifts towards a circular economy, waste to energy facilities can play a role in diverting waste from landfill and creating energy that can be used by industry or exported into the grid.”

A circular economy prioritises waste avoidance, waste reduction, material reuse and recycling, and as part of the circular economy policy, Recycling Victoria: A new economy, the state government has committed to placing a cap of one million tonnes per annum on the amount of waste that can be heat treated to make energy.

The cap is designed to prevent over-reliance on thermal waste to energy, as over-reliance has the potential to undermine efforts to decrease waste generation and increase recycling in the long term.

“Victoria will continue to implement new waste and recycling regulations and standards as part of the most significant reform to waste and recycling in our state’s history,” a state government spokesperson said.

Nationals Member for Gippsland South Danny O’Brien also welcomed the recent advancements in the Maryvale EfW project.

“The Maryvale project is an exciting opportunity to safely turn waste products into valuable, dispatchable electricity production,” Mr O’Brien said.

“It is a project that solves at least two problems in one go – disposing of waste and generating baseload power – and it’s an important job creator for the region.

“With Labor’s disastrous decision to shut down the native timber industry costing up to 200 jobs at Maryvale already this year, good news on the jobs front is always welcome.

“The Maryvale mill is not only a major employer in the region, but it generates significant indirect jobs and economic activity in the plantation sector throughout Gippsland, particularly in my electorate of Gippsland South.

The EfW plant will help shore up its future in an environment of uncertainty created by the Labor Government’s policies.”

Federal Member for Gippsland Darren Chester said he was pleased to see the project was progressing with the grant consortium partners Opal, Veolia, and Masdar Tribe Australia secured under the previous Federal Government.

“The signing of the grant agreement for $48.2 million under the Manufacturing Collaboration Stream of the Modern Manufacturing Initiative is the next stage in this exciting project,” Mr Chester said.

“The facility will be the first of its kind in Australia to recover heat and power from municipal and commercial waste and support large-scale manufacturing in the Latrobe Valley.

“The proposed Maryvale project will be a first for Victoria, but the technology is well developed around the world, and also here in Australia.

“I took a close-up look at a similar facility which is currently under construction south of Perth in Western Australia earlier this year.

“The Maryvale project will take waste that would otherwise end up as landfill and convert it to energy for the mill and potentially other users,” Mr Chester explained.

“Using advanced European technology, it will divert 325,000 tonnes of waste per year from landfill and create an estimated 500 jobs during construction plus 455 ongoing roles.

“This is a world-class and environmentally sustainable project that will support the economic recovery of our region after several setbacks in recent years. Hopefully, all levels of government in Gippsland will work together with the proponents to deliver this exciting project.”

With the environment a key strategic area for the Wellington Shire Council, which continues to take actions to work towards a sustainable future, the council supports the pending Maryvale EfW facility as an asset to support the region’s sustainability and green energy targets.

“Wellington Shire Council is continuing to investigate landfill alternatives for residual waste that provides best value to the Wellington community,” a Wellington Shire Council spokesperson said.

“Council acknowledges the Maryvale Energy from Waste project as a key opportunity for the region in this regard, and particularly the economic support and jobs that will be achieved from this project.”

The Maryvale EfW project has EPA Victoria regulatory approvals for construction.

“In November 2018, EPA issued Paper Australia Pty Ltd with a Development Licence that allows the construction of a Waste to Energy facility capable of thermally treating 650,000 tonnes per annum of residual Municipal Solid Waste (MSW) and residual Commercial and (non-hazardous) Industrial waste,” an EPA Victoria spokesperson said.

“The Development Licence imposes conditions covering issues such as emissions, noise, wastewater, disposal of ash, management of incoming waste, monitoring and sampling, and reporting of monitoring results.”

Latrobe City Council has also issued regulatory approvals for the construction of the Maryvale EfW facility.